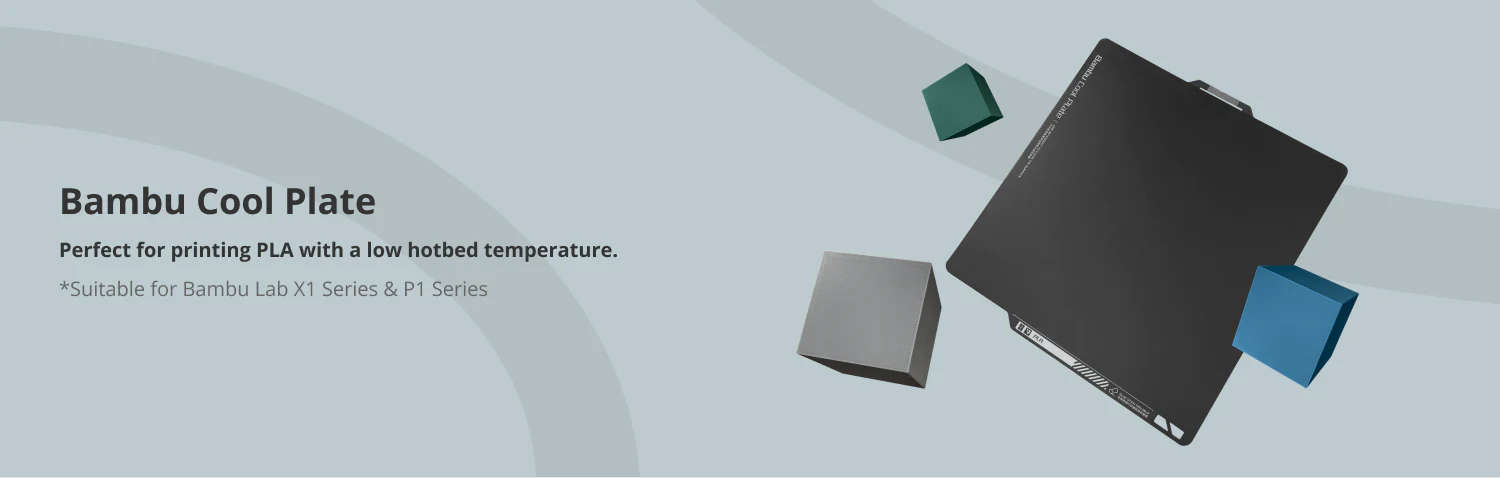

Bambu Cool Plate

Description / Bambu Cool Plate

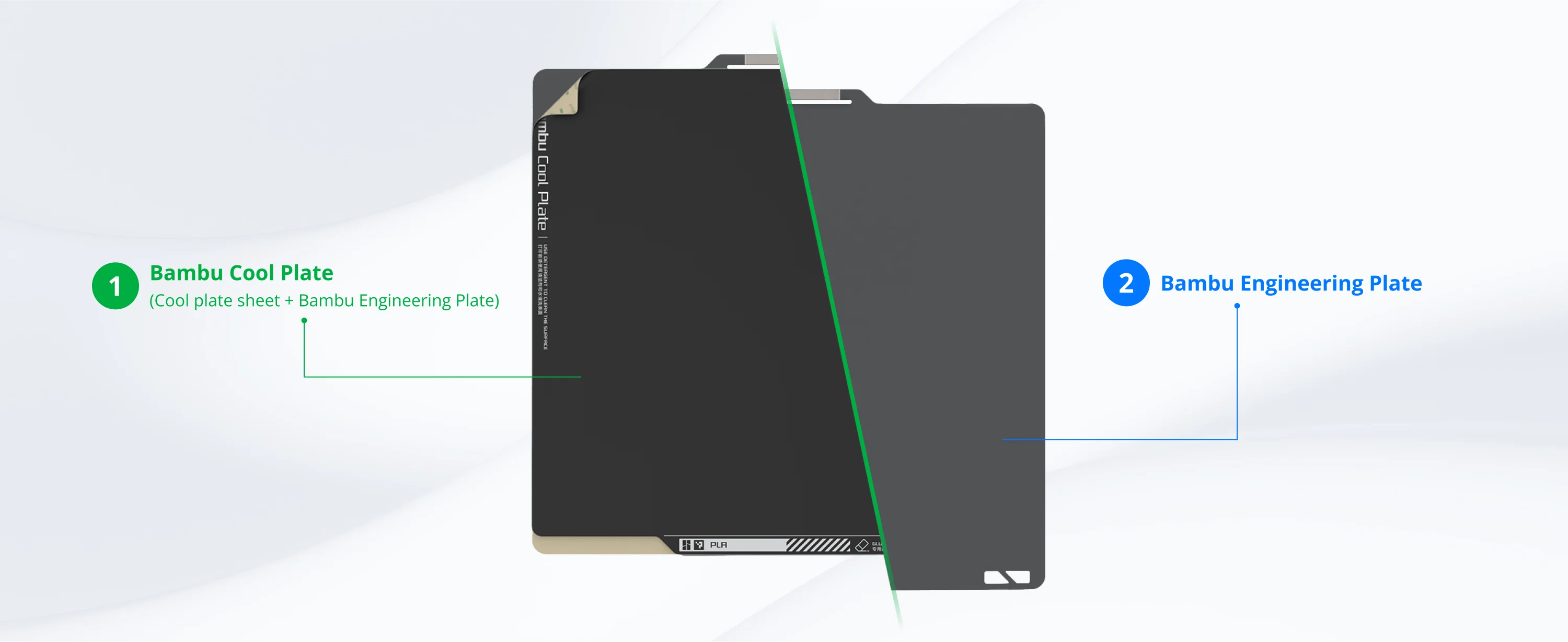

One side: Bambu Cool Plate= Cool plate sheet + Bambu Engineering Plate

The other side: Bambu Engineering Plate

1. Bambu Cool Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

Benefits

- Works best with low glass transition temperature filaments as it can be used at a low temperature for the heatbed

- Works well with the Automatic Calibration for Flow rate and does not interfere with the LIDAR

- Smooth texture on the surface of the print

- Excellent adhesion and easy print removal

- Can be replaced by the user

Downsides

- Cannot be used without glue stick as the surface can be easily damaged if glue stick is not used

- It is not recommended for high-temperature materials as bubbles can form underneath the print surface and cause damage

- Can be more fragile compared to the Engineering Plate or Textured PEI Plate

2. Bambu Engineering Plate

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

-

Step 1:

Step 1:Align the plate with the fixed points of the platform with the name of the plate facing you

-

Step 2:

Step 2:Lower the plate and secure to the magnetic platform

More Information

| Manufacturer | Bambu Lab |

|---|